Offer phase

// On-site customer consulting at FAIST

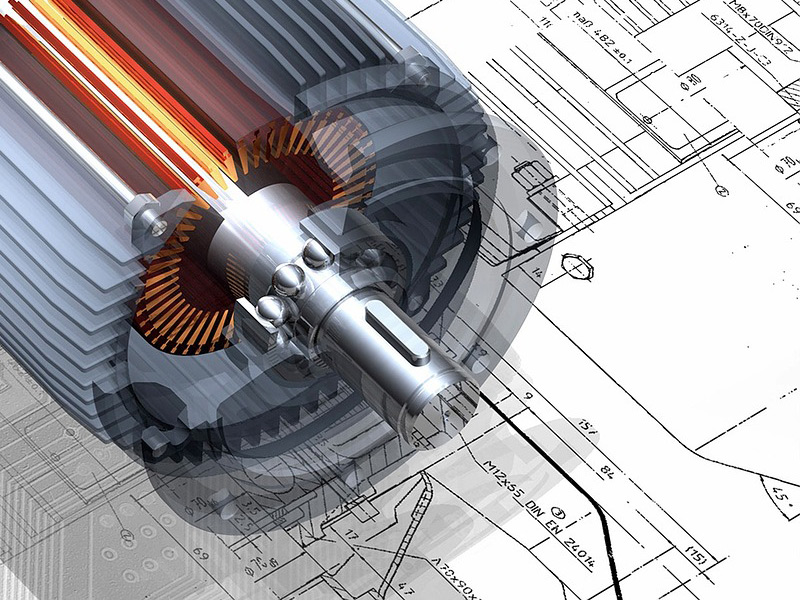

// Engineering

// Preliminary layout

// Acoustic consulting

// Ventilation and exhaust layout

// Electrical planning

// Offer drawing as per your requirements

Implementation in design

// Acoustic and CFD planning and layout

// Strength analysis (testable)

// Electrical planning and supply (e.g. lighting, ventilation control)

// Drafting of shop and assembly drawings

// Modern 3D environment (NX)

// Well-trained and experienced techncical staff (technicians/engineers)

// Risk analysis

// CE-compliant documentation

Procurement

// Securing of material supply (in-house production and on-site assembly)

// Supplier management; long-standing cooperation with regional and global partners

// Experienced procurement team

// Identification and realization of cost savings

// Continuous optimization of procurement processes

// Close collaboration with design, project management and production

Production

// In-house production, but also external production in eastern Europe and China

// Steel construction (steel, stainless steel and aluminium welding)

// Sheet metal construction (fully automatic uncoil equipment, punch-nibbling machine, trimming press, swivel bending machine, flow production for panels)

// In-house powder coating (own and job coating)

Packaging and shipping according internationally applicable guidelines and customer requirements